About the Six Sigma Component | ||

| ||

When you use the Six Sigma component a product or process is simulated repeatedly, while varying the stochastic properties of one or more random variables, to characterize the statistical nature of the responses (outputs) of interest. The “sigma level,” or probability of satisfying design specifications, is reported, along with statistics on performance variation.

The run mode used by the Six Sigma component is determined when the model is created in the Isight Design Gateway. You cannot alter the run mode from the WebTop. The following run modes are available:

-

Six Sigma Analysis. Isight evaluates the quality level of a single design. A set of points are sampled around the mean value point—the current design point—based on the analysis type and technique that you select.

-

Six Sigma Optimization. Isight performs a six sigma analysis at each new design point selected during a robust design optimization strategy. The focus of robust design optimization is to search for robust or flat regions of a design space to reduce the effects of variations in uncertain design parameters, while satisfying design requirements with a high degree of certainty (reliability or sigma level).

If the loaded model is configured with the Six Sigma Optimization run mode, you can select and configure the optimization technique in the Optimization component web editor, which appears above the Six Sigma component in the model’s simulation process flow.

Regardless of the run mode selected, you can choose from three analysis types:

- Reliability Technique. The focus in structural reliability analysis is to assess the probability of failure—the probability of violating a constraint—of a structural component or system, resulting from performance (output) variation caused by the variation of uncertain, random (input) variables.

- Monte Carlo Sampling. Monte Carlo simulation techniques are implemented by randomly simulating a population of designs, given the stochastic properties of one or more random variables. The focus is on characterizing the statistical nature (mean, standard deviation, variance, range, distribution type, etc.) of the performance responses (outputs).

- Design of Experiments. In a Design of Experiments analysis a design matrix is constructed that specifies the values for the design parameters (uncertain parameters in this context) for each sampled point or experiment.

The techniques that are available in the Six Sigma component depend on the analysis type that you select, as shown in the table below:

| Analysis Type | Available Techniques |

|---|---|

| Reliability Technique | First Order Reliability Method (FORM) Importance Sampling Mean Value Method Second Order Reliability Method (SORM) |

| Monte Carlo Sampling | Descriptive Sampling Simple Random Sampling Sobol Sampling |

| Design of Experiments | Box-Behnken Central Composite Data File Fractional Factorial Full Factorial Latin Hypercube Optimal Latin Hypercube Orthogonal Array Parameter Study User-Defined |

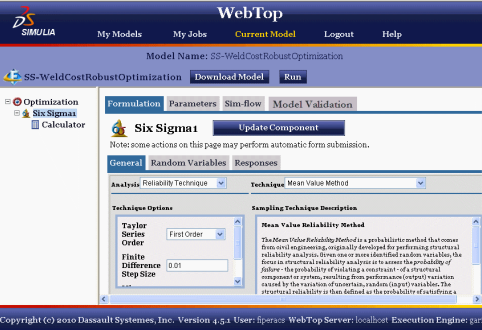

The following figure shows the Six Sigma

Component WebTop Editor.

To view the details of the Six Sigma component, access the model containing the component, select the Six Sigma component whose information you want to view using the navigation area on the left side of the interface, and click the Formulation tab.

For more information on accessing the model, see Viewing and Manipulating Model Parameters.